For The Love Of Horses

By Frank J. Buchman

Bronc Riding Accident Leads To Making

Rodeo Equipment For World Champions

Equipment is as important as a cowboy’s ability to become a world rodeo champion.

“As rodeo has changed during the past half century so has equipment used by the contestants,” said Neil Barstow.

“It sounds strange to spectators, but rodeo equipment today is technically engineered,” insisted the rodeo equipment manufacturer.

“Every rigging used by champion cowboys is custom designed to their specific request,” Barstow said.

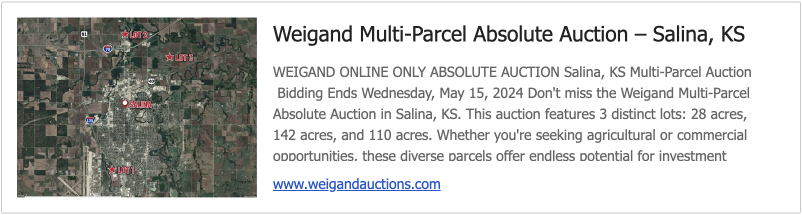

Equipment manufactured by Barstow Pro Rodeo Equipment, Corsicana, Texas, is preferred by the world’s champion rough stock riders

“Many of the best Professional Rodeo Cowboys Association bareback bronc riders and bull riders are using our equipment,” Barstow verified.

Actually, the “Top 15” bareback bronc riders at the last National Finals Rodeo in Las Vegas had Barstow riggings.

“Our goal is, and always has been, to build the best rodeo equipment made,” Barstow insisted. “We are one of the few manufacturers cowboys can call and place their order with the same people who build it.”

A family business with worldwide demand Barstow Pro Rodeo Equipment began by accident. The business might have never started if there hadn’t been a rodeo misfortune.

“I broke my neck in a bareback bronc riding wreck competing at a college rodeo in Columbus, Nebraska,” Barstow said. “I was in the hospital six weeks and didn’t do much of anything for several months.

“I started taking a bull rope apart, putting it back together, and decided to make my own rope,” he remembered. “Before long other college cowboys asked me to braid their bull ropes and demand for ropes continued to increase.”

Growing up at Johnson in Stanton County, Kansas, Barstow always wanted to be a cowboy. “We later lived in Colorado and then in South Dakota where I got my first chance to rodeo.

“My grandpa paid my entry fee to compete in bull riding,” he smiled. “I hardly knew what a bull rope was. But I made one of sorts, got on the bull and landed on my head.

“I saw the other cowboys’ bull ropes and decided I’d have better equipment in the future,” Barstow said.

Competing in bareback bronc riding and bull riding, Barstow was on the rodeo team at Fort Hays State University.

Upon graduation in 1970, he became a regional representative for Vigortone Feeds in Kansas.

“I continued to compete in rodeos while making and selling bull ropes,” Barstow said. “Cowboys also wanted other equipment so the business grew.”

In 1979, Barstow and his wife Belinda bought Jim Houston Rodeo Equipment of Burkburnett, Texas. They moved the company to a building at the fairgrounds in Beloit, Kansas, selling wholesale as well as retail.

It was a family business with their three daughters working too. “They didn’t always like to sweep and clean up, but that’s all part of it,” Barstow said.

From college and amateur cowboys using Barstow gear, professional rodeo cowboys soon demanded the precision-made equipment.

Known for bareback riggings and bull ropes, the business also originally manufactured saddles. Now only bronc saddles made by another manufacturer are sold retail.

Barstow developed his own line of specialized riding boots used by rodeo cowboys and performance horse trainers.

Each Barstow bareback rigging is individually handcrafted using only the finest materials. “Our Pro Flex riggings are in highest demand, as we constantly make changes to perfect them,” Barstow said. “Before a new rigging is marketed, it is tested by the best cowboys in the world.”

Each bareback rigging takes several weeks to complete with tedious design of the rawhide handhold. A finished bareback rigging built to order sells in the $700 to $800 range.

“We really had a high demand in the 1990s selling an average of 30 riggings a week,” Barstow said. “Bareback participation declined during the early 2000’s, but has been on the rise in recent years.”

Originally braiding bull ropes with manila, Barstow now makes long-wearing poly ropes, rot, mud and moisture resistant.

One bull rope requires about eight hours to braid and sells in the $300 range.

Chaps are also custom made to order for rodeo events and ranch work. Spurs, halters, gloves, about anything used by cowboys and cowgirls are sold.

Coronavirus impacted sales as rodeos slowed down this year, but Barstow Pro Rodeo Equipment demand is again expanding.

“Our equipment is still handmade one item at a time,” Barstow assured. “This is important in a time when much of the rodeo equipment available is mass-produced here and in foreign countries.”

With daughters Danna and Mandy also living in Texas, Barstow is retired from everyday operations staying home with Belinda.

“Our daughter and son-in-law Erica and Brent Hodge now own and operate the business with a dozen dedicated employees,” he credited.

“The customer is always Number One, whether a beginner or a seasoned professional. Satisfaction is the top priority,” Neil Barstow stated.

CUTLINES

Before retiring in 2013, Neil Barstow of Barstow Pro Rodeo Equipment in Corsicana, Texas, built a bareback rigging for Steven Dent (right), 10-times National Finals Rodeo qualifier. Holding Dent’s baby son, Brent Hodge, Barstow’s son-in-law and his wife Erica now own and operate the business.

Neil Barstow is with three of his six grandchildren.

Barstow Pro Rodeo Equipment builds bareback bronc riggings to a rodeo cowboy’s specific request.

Long-wearing poly bull ropes made by Barstow Pro Rodeo Equipment are rot, mud and moisture resistant.

Miss Rodeo America 2019 Taylor McNair from Mississippi won the $1,000 Women’s Professional Rodeo Association Chap Scholarship wearing chaps made by Barstow Pro Rodeo Equipment.